In this guide, you will find everything you need to know to install your mezzanine, staircase or railings in outdoor spaces. Before you start, it's important to know that most MezzaninesOnline products can be installed outdoors, but there are a few considerations to keep in mind!

We will guide you step by step, from the calculation and consideration of snow and wind loads, to details on maintenance and best practices to assure the strength and durability of your structure. Let's get to it!

Climate and Structural Considerations

Installation Basics

Water Accumulation Prevention

Final details

Preservation of materials

Contact

Climate and Structural Considerations

When installing our outdoor structures, we must take into account the forces caused by snow and wind, which vary according to geographical location and altitude.

These considerations are essential and have been taken into account in the calculation of the structures, with certain maximum values. These values must be compared with those of the area where the mezzanine will be installed to check that they are not exceeded.

Snow load

It is essential to take into account the amount of snow that could accumulate. Imagine the snow load as an extra weight on the mezzanine. To calculate it, we simply subtract this value from the maximum capacity that the mezzanine can support, taking into account its dimensions.

As a guideline, TecroStar mezzanines have a minimum capacity of 200 kg/m². Therefore, a mezzanine can support a large amount of snow.

Wind

When installing mezzanines outdoors, it is crucial to consider how wind can affect their stability. There are two main scenarios to consider:

Allowing air to pass underneath

In this case, the wind can circulate freely underneath the mezzanine. This helps to reduce the wind pressure on the structure.

Against existing facades or walls

In this position, the wind can create suction that exerts upward pressure on the mezzanine floor.

For the purpose of estimating wind strength, it is assumed that the mezzanine can withstand a reference speed of up to 62 mph. However, it is essential to consult local regulations to ensure that the safety limits are not exceeded.

Under no circumstances is it recommended to close the sides of the mezzanine or place enclosures over it, as this could generate horizontal forces not considered in the initial calculation.

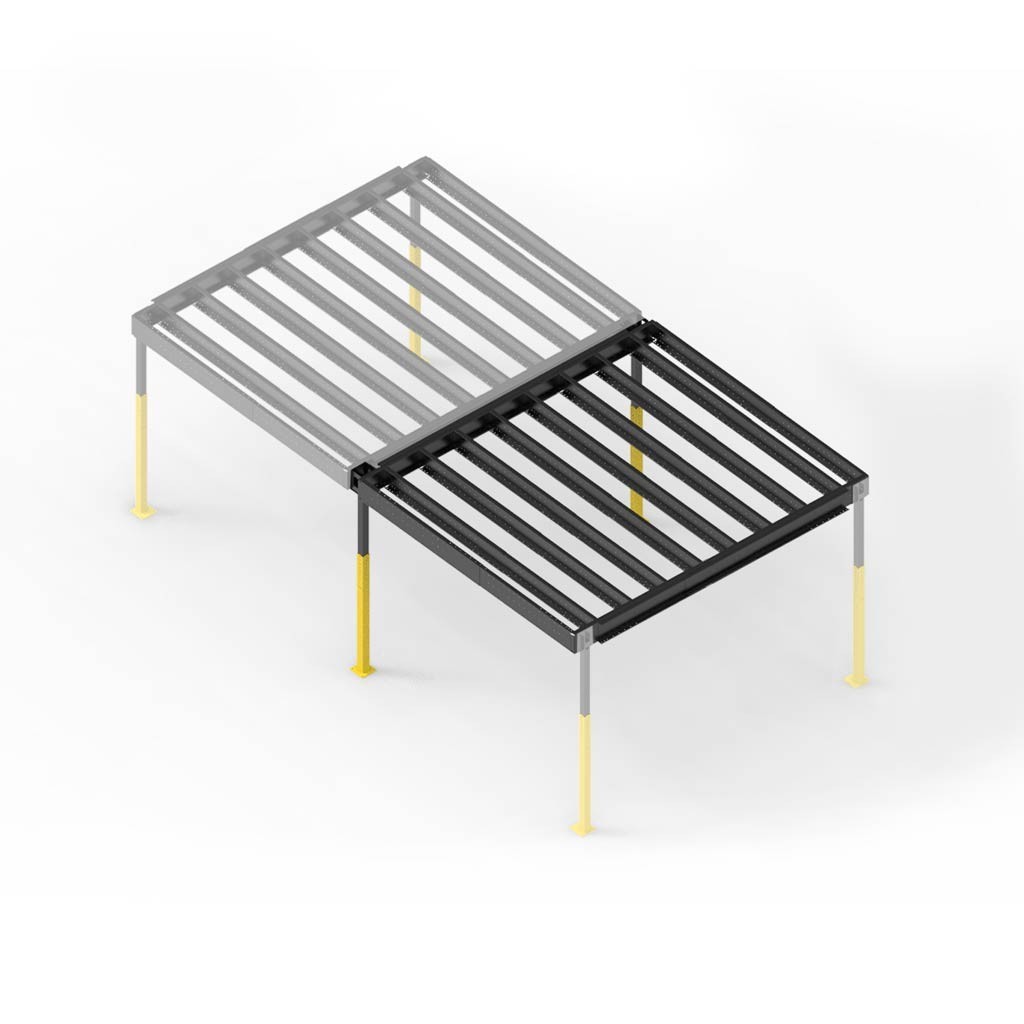

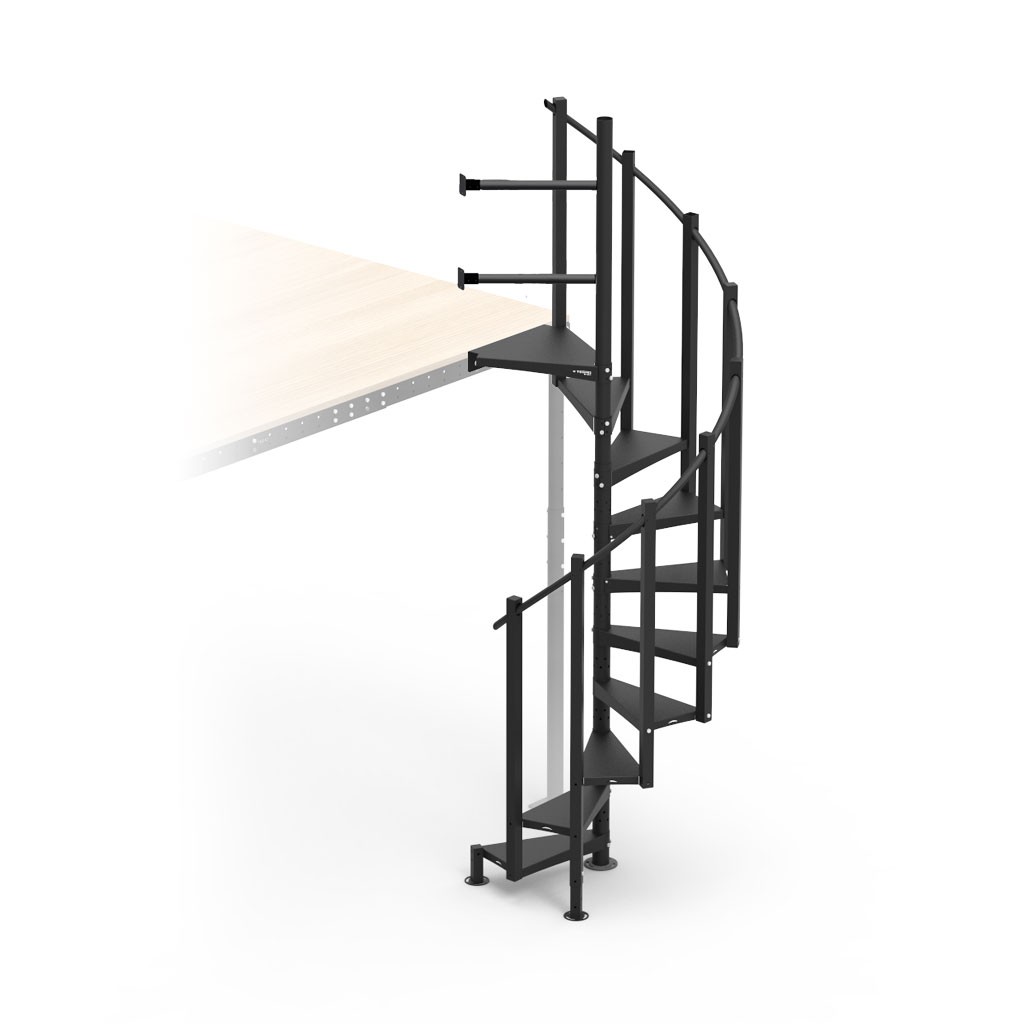

Enclosure 1

Enclosure 2

In either case, it is essential to ensure the lateral stability of the mezzanine. For more information on how to do this, see the 'Lateral stability' section.

Installation basics

Anchoring to the ground

To ensure that the mezzanine is securely anchored to the ground, it is important to attach the columns to a solid base that can support their weight. There are two common situations:

On concrete surfaces

To ensure stability, it is recommended to attach the columns to a resistant surface. As a guideline, we recommend using 50x50cm and 50cm high footings with 150x150x8mm single mesh, or 30cm thick concrete slabs with 150x150x8mm single mesh.

- On grass or soil type surfaces

Some form of concrete footing or slab will be required. In these cases, a good option may be to use the PILOEDRE modular foundation system or similar. This system provides a specific and effective solution for this type of terrain, guaranteeing a safe and durable installation without complications.

TecroStar offers guidelines or recommendations on different types of footings or foundations required under the columns but the final verification of the resistance of the ground is the responsibility of the client or the technician in charge of the project.

Lateral stability

The lateral stability of the mezzanine must be guaranteed by wall fixings and bracing systems, following the general criteria indicated in the FAQ attaching the mezzanine

Wall fixings to existing walls

Bracing systems

Without fixing and bracing

Water Accumulation Prevention

Slope and Drainage

Finally, when laying the mezzanine deck, it is advisable to leave an overhang at the bottom of the slope, extending about 100 mm beyond the primary beam. This will ensure the protection of the beam and prevent its direct contact with water, thus ensuring its durability and good condition over time.

Final details

Final tips to protect your mezzanine from water

Once the mezzanine is installed, it is important to make some final adjustments to protect it from water and ensure its durability.

Preservation of materials

When choosing TecroStar for your outdoor projects, the durability and strength of the materials are key factors. In this section you can see some tips on how to get the most out of your structures and ensure they last a long time.

Lacquered steel parts

At TecroStar, we rely on steel as the predominant material in all our structures. We rely on this material to create products that are robust, resistant and able to stand the test of time.

For lacquered steel parts you can choose between two options: without waterproof treatment and with waterproof treatment. Below, we explain the characteristics of each type and how to preserve them.

The Waterproof treatment adds an extra layer of protection to the steel parts, protecting them from rust due to weather conditions. These parts have several layers:

- Zine electroplating: we apply a layer of zinc at low temperature to protect the parts from rust.

- Chromium passivation: to increase the resistance of the parts and prolong their service life.

- Lacquered with polyester powder coating: for a perfect finish and increased protection against rust.

- Paint-coated galvanised steel parts: galvanized steel parts (e.g. metal steps) cannot be subjected to the standard Steel Waterproof treatment, as the electrolytic zinc plating process is not compatible with already galvanised materials. However, they can be painted afterwards to create a double protective barrier that is just as effective as the waterproof treatment of other metal parts.

Preservation

To keep waterproofed parts in optimum condition, it is important to carry out regular visual inspections.

As rust begins to set in, the outer protective layers may weaken, deteriorating from the outside inwards, where the steel structure is located.

At the beginning, what we call white rust appears, which affects the zinc layer. This is the time to take measures to maintain the treatment and prevent further deterioration. If you detect areas affected by rust, in this case we recommend applying an additional coat of paint to protect them.

If the rust penetrates into the steel and red rust appears, we recommend sanding and painting the affected area.

Our steel parts are coated with a special outdoor coating of thermosetting polymerised polyester powder paint, with a coating thickness of between 60 and 80 microns.

Over time, it is normal for exterior parts to experience wear and tear and they may require minor touch-ups or maintenance to maintain their optimal appearance and functionality. In environments near the sea this maintenance should be performed more frequently.

Preservation

Regular care is essential to prevent rust and ensure the durability of the parts. To prevent rust, we recommend regular visual inspection. Pay special attention to areas with sharp edges, weld seams and corners where rust or loss of shine may appear. In this case you can sand the affected areas to remove the rust and then apply an additional coat of paint.

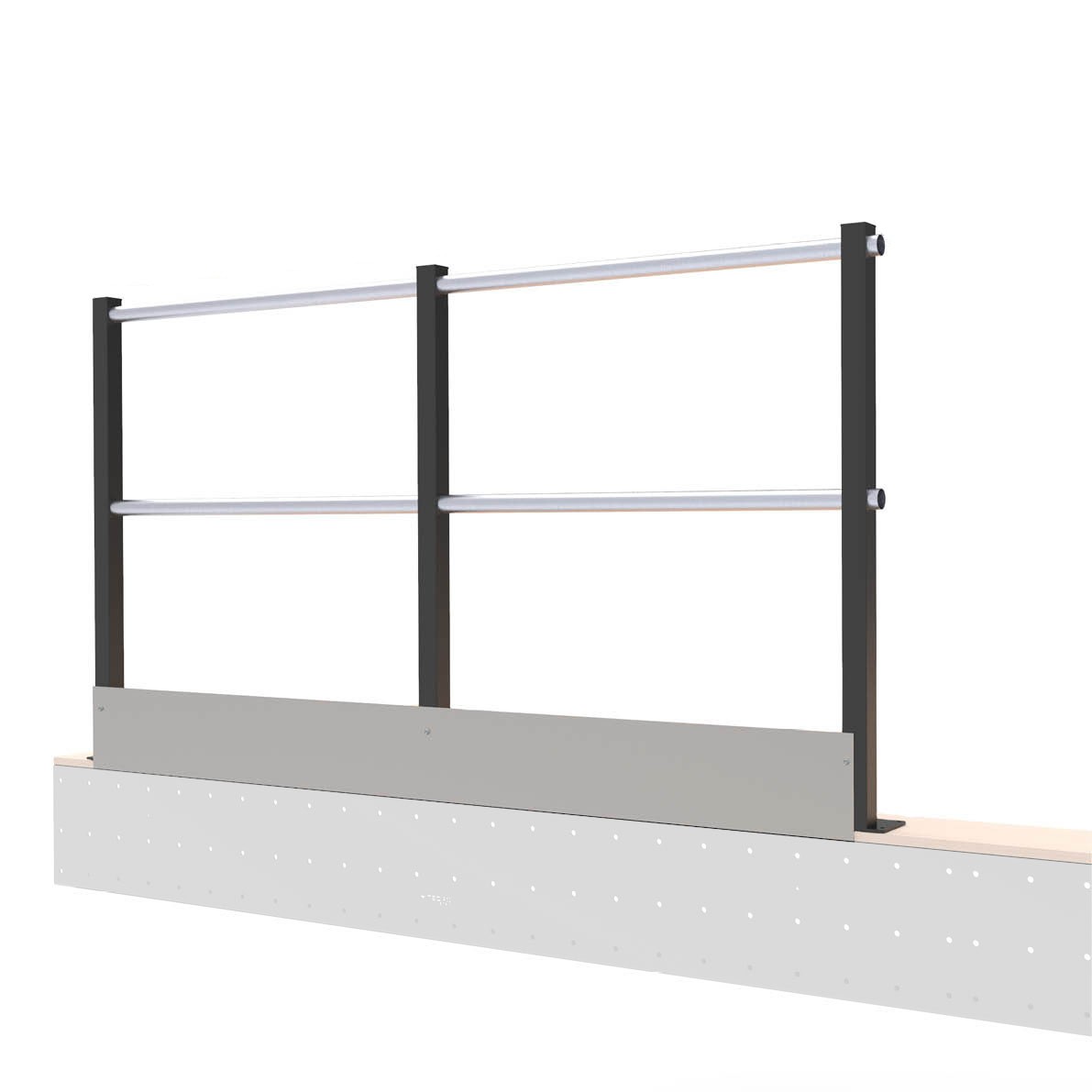

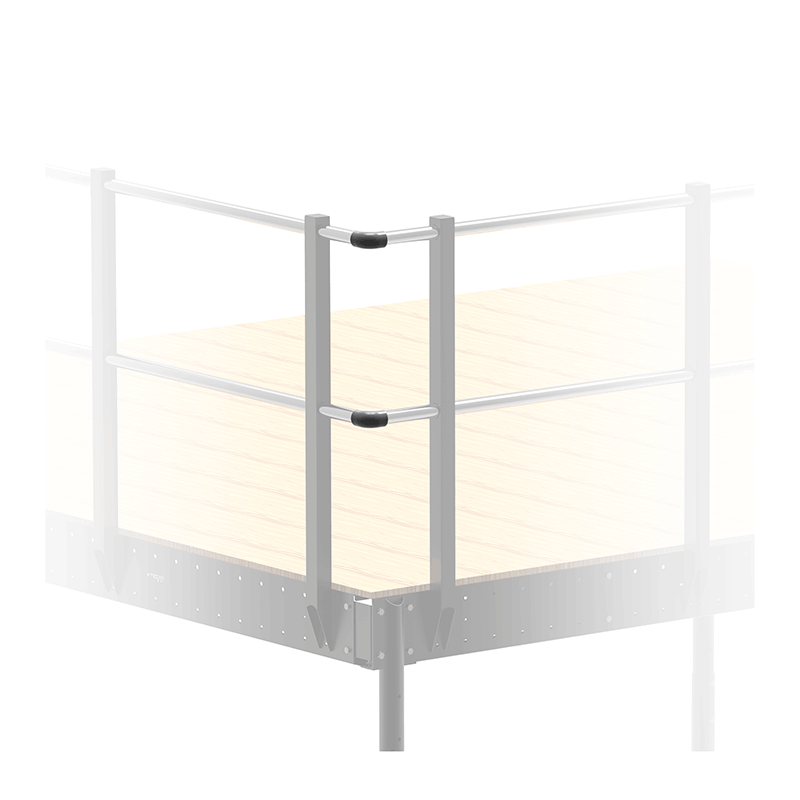

Aluminium handrails

The aluminium handrails of the railings do not require any special maintenance, as they all undergo surface treatments that guarantee their performance outdoors (anodised silver, black lacquered or with a wood effect).

Galvanised steel parts

Steel parts with a galvanised finish cannot undergo the Waterproof Steel treatment as the two finishes are incompatible. These types of parts may show first signs of rust on the edges over time, as these areas are not protected. We recommend painting these parts or selecting other parts to which the Waterproof Steel treatment can be applied.

Wooden parts

Wooden parts, such as steps, stairs and handrails, require specific care to preserve their quality over time. It is essential to apply water-resistant and sun-resistant paints or varnishes to prevent moisture penetration and cracking of the material, which could cause it to lose its mechanical and aesthetic characteristics.

The customer can apply wood stain (*) or specific waterproofing treatment for wood to these elements, which protects the surface against damp and sun.

It is important to carry out regular maintenance of these wood pieces, making sure that the surface coatings applied, such as varnishes or paints, have not deteriorated. If necessary, refinish them to keep them protected from the sun and damp.

(*) This is a more suitable product for outdoor use than varnish because it is highly resistant, breathable and does not form a waterproof layer on the material to which it is applied, it regulates damp, provides a waxy finish and offers a wide range of finishes.

Panel floor of the mezzanines

The load-bearing floor of TecroStar mezzanines consists of structural plywood panels (for the S, M and L ranges) and structural chipboard panels (for the XL range), both of which are water-repellent. Ideal for damp environments or sheltered outdoor areas. This means that they withstand damp well but should not be in direct contact with water.

If you are considering an alternative to create mezzanine flooring suitable for outdoor use, it is important to ensure that the panels are waterproofed and protected against sun and UV rays.

To protect the flooring of the mezzanine from rain and other types of precipitation, avoiding direct contact with water, we recommend installing Outdoor Decking. This provides a waterproof and breathable layer, ensuring better performance in outdoor conditions.

Other products not suitable for outdoor use

It is not advisable to place products with electrical parts outdoors (such as lamps or ladder lifting kits), or products made from materials that do not withstand weather conditions and damp well. For example:

- Lighting Products

- Products with electrical components

- Ladder lifting kit

- Wall-mounted folding ladder

- Retractable stairs

- Public use handrail

- Stairs for public use