Design and manufacturing process

Our production line is oriented towards quality criteria, paying special attention to safety and functionality. Thanks to the close contact with our customers, we observe lots of upgrades, new products and needs that allow us to keep on improving.

Firstly, we conduct a market research, analyzing social needs and demands and observing existing products. Then, we think about the different alternatives, related to the possible options to be developed, from which we choose the most appropriate procedure. To develop the idea, we take into account the providers involved and the time planning.

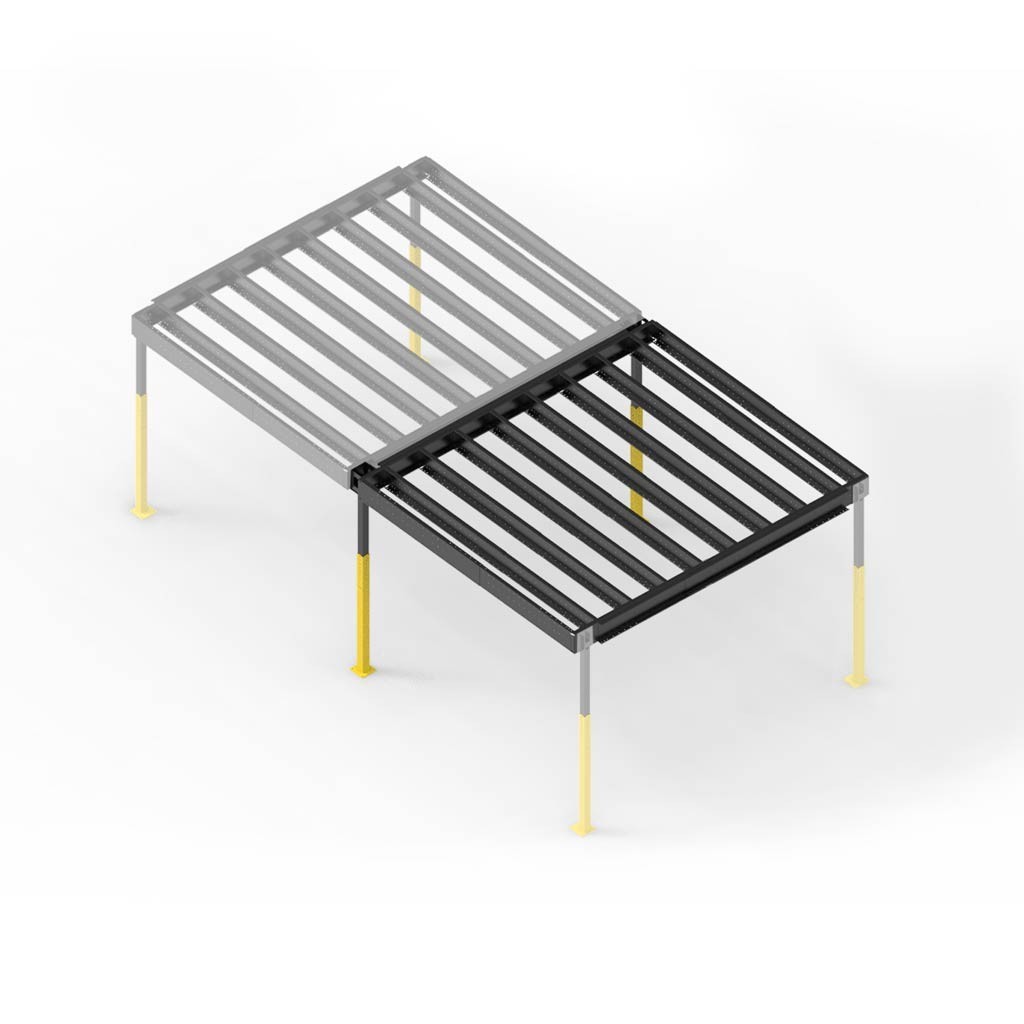

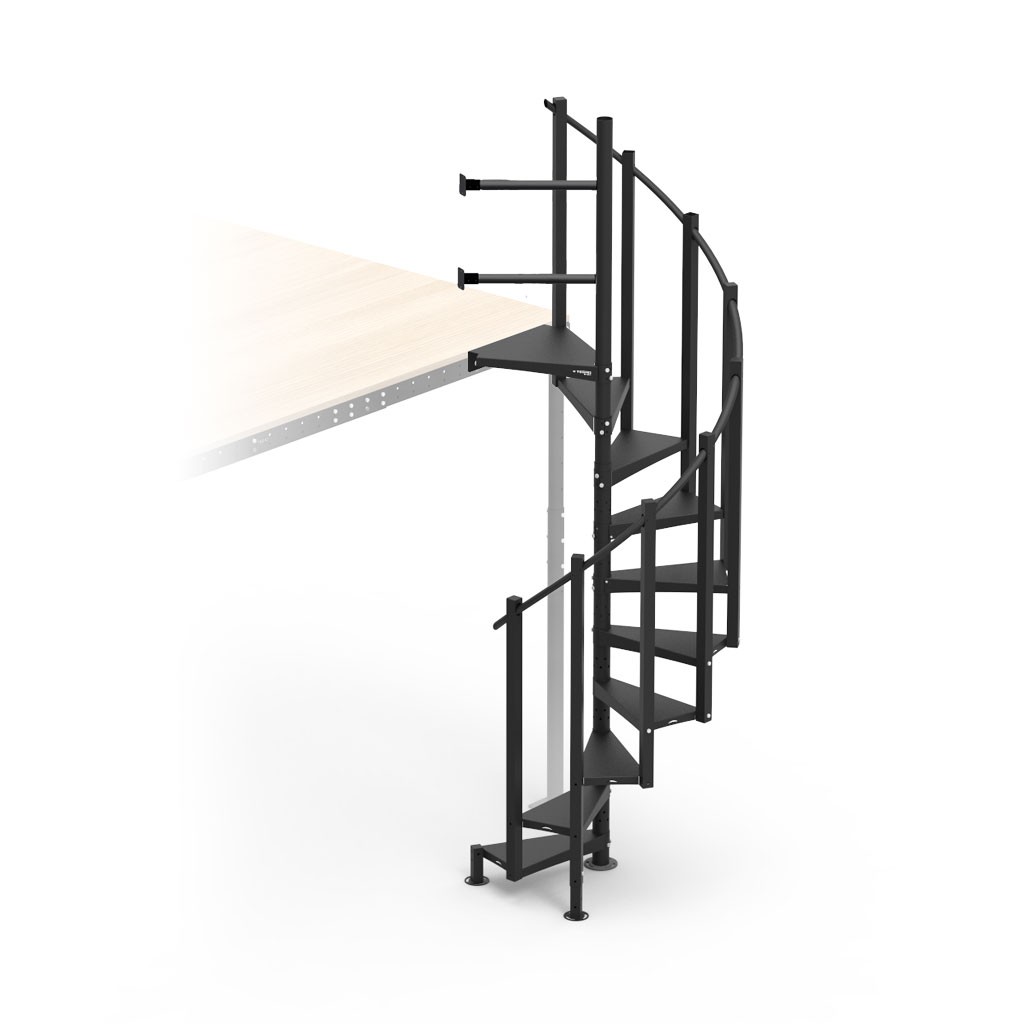

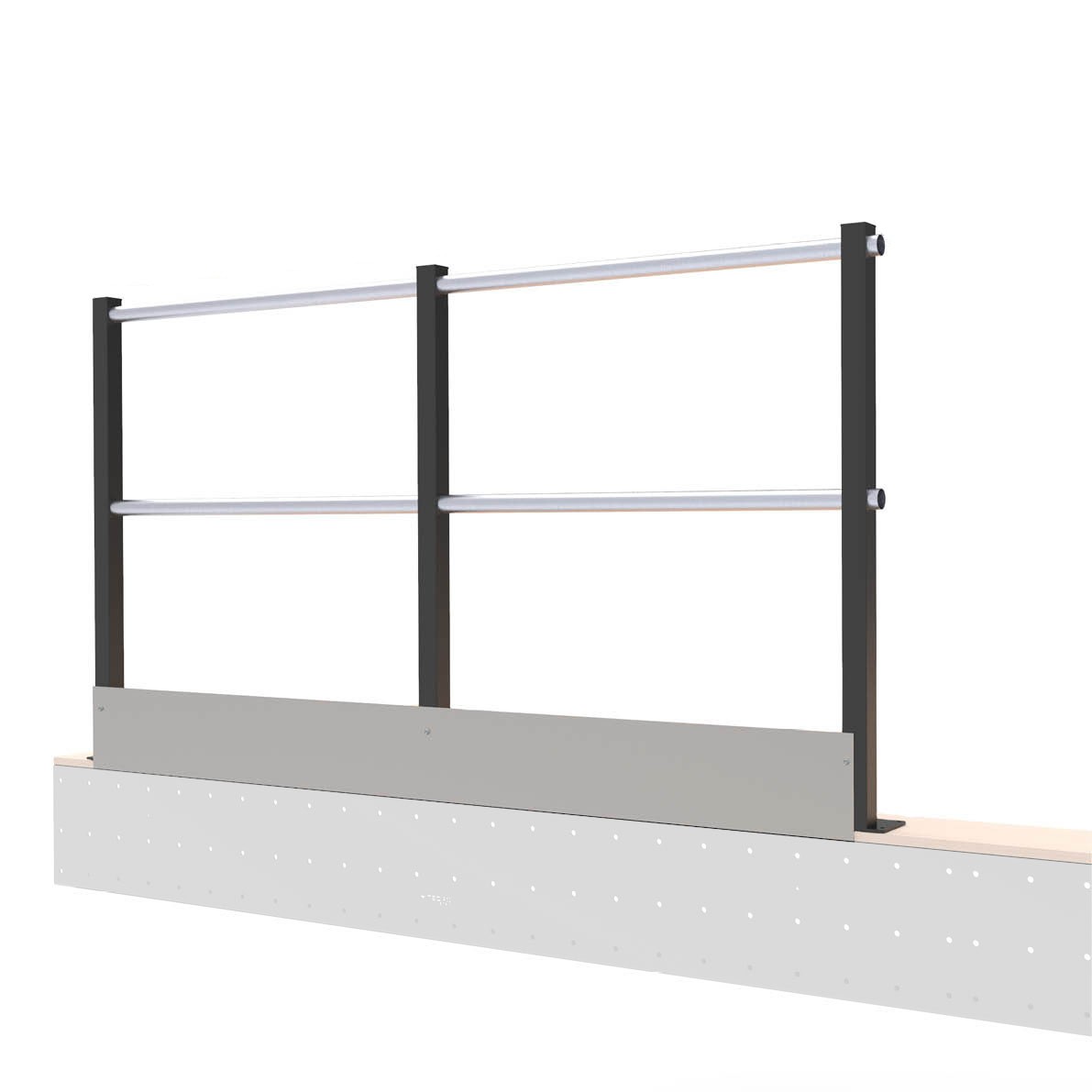

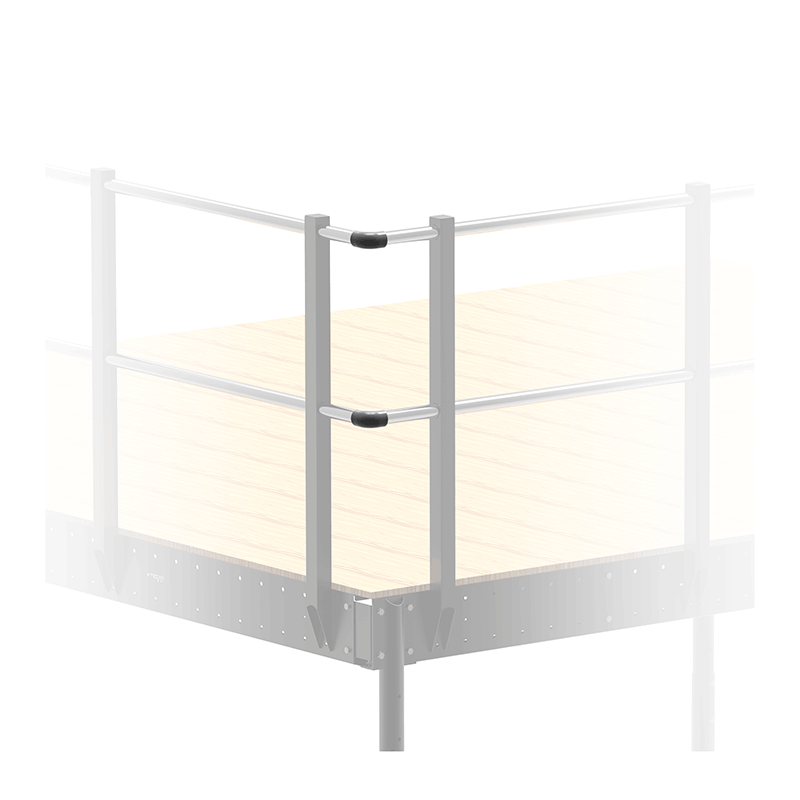

The next step is the pre-design of the product, with the realization of diagrams and plans, the definition of preliminary characteristics and the estimation of costs. Next, a feasibility study is carried out and the prototype is designed. Then, calculations and assembly are carried out, with prototype plans, cuttings, choice of materials and finishes. After these stages in the manufacturing process, this first product is tested to verify the validation. If everything is correct, the prototype request is made, the technical and assembly documentation is developed, the prototype tests are carried out and the tests and installation are carried out, observing the possible problems of operation and assembly.

Once again, a validation test is carried out again and, if all the conclusions are optimal, the product is standardized with technical and commercial procedures. In the last phase of the process, the cuts are made, the products are coded and the manuals are designed. Then the descriptions are written, the images are designed and the videos of the products are edited. Finally, prices are established and proceeds to the start of the sale.